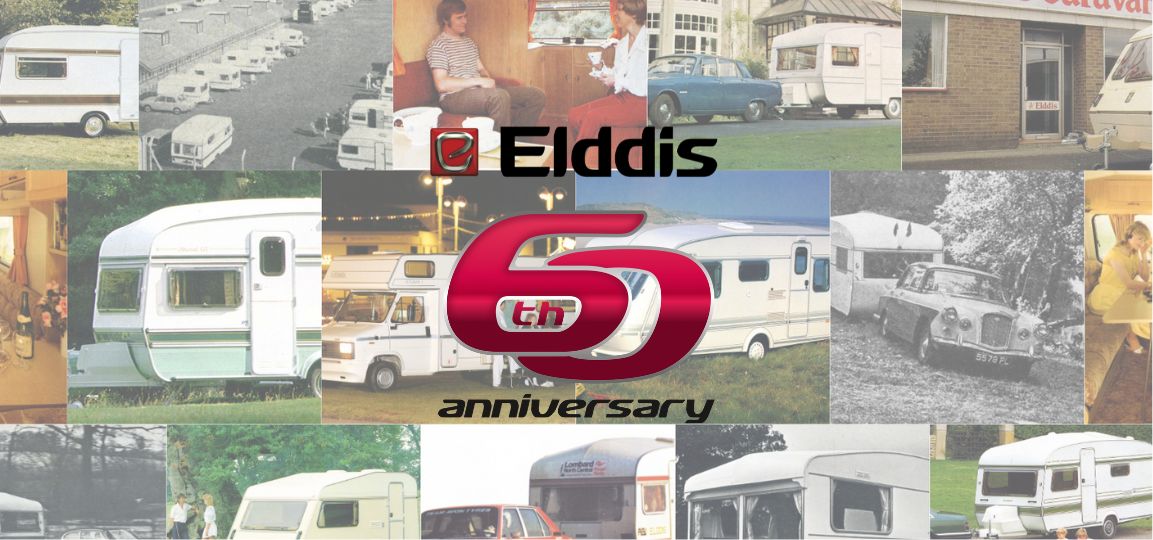

Inspiring travel since 1964

Multi-award winning caravans, motorhomes and campervans for over 60 years

You will have seen our vehicles on the road, en-route to an exciting holiday destinations or on a spontaneous road-trip adventure. Our Elddis Caravans, Motorhomes and Campervans - instantly recognisable by their head-turning style and proud Elddis livery!

Class-leading with over 60 years manufacturing experience

Our UK manufacturing plant is one of the largest caravan, motorhome and campervan manufacturers in the UK. Based in Consett, County Durham, we have a rich heritage of leisure vehicle design and manufacture, spanning nearly six decades.

Elddis is renowned for creating multi-award-winning Caravans, Motorhomes and Campervans

Whichever type of vehicle best suits you, you’ll find Elddis has a vast choice of models, layouts and sizes - all built with your wants and needs very much in mind. We’re building dreams, but keep our prices super-competitive to help you make your adventures a reality!

Featured News

Stay tuned for featured Elddis news! From product updates to media reviews and captivating customer stories, everything you need to know is right here.

Elddis Special Offers!

Discover our Elddis Special Offers!

The New Elddis Ranges Are Here - Get Your Quote

If you weren’t able to come to this year’s show, but have your heart set on a new Elddis, make sure you try out our Get Your Quote service.

Latest News

Keep up-to-date with all the latest Elddis news, including product updates, media reviews and our Customer stories. It’s all here!

Win tickets to Clubfest 2024!

We're giving away two pairs of 4-day family tickets to this May's Clubfest at Weston Park

Elddis Autoquest 196 Motorhome Review - MMM Magazine

MMM Magazine review the family friendly Elddis Autoquest 196

Elddis Avante 868 Caravan Magazine Review

Caravan Magazine review the Elddis Avante 868